Warehouse Robotics Solutions For Businesses In New Jersey And New York

More and more companies are requiring automated and robotic solutions. If your facility is one of them, Barclay Brand Ferdon is well able to provide you with innovative, affordable solutions. From our headquarters in South Plainfield, New Jersey, we supply North and Central NJ, as well as four counties in New York, with materials handling solutions. These include robotic forklifts and other warehouse robotics, which can help you to improve productivity and gain an advantage over your competitors.

Our Automation Robotics Selection

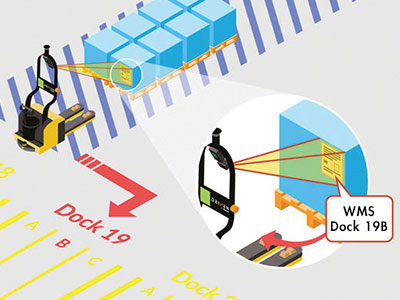

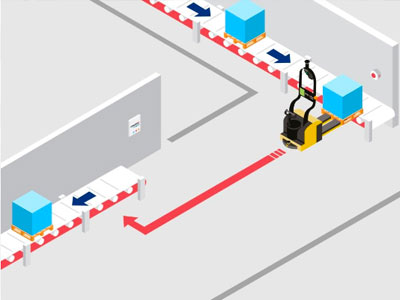

The best automated solutions are those that adapt to your needs, which is why we’ve partnered with Yale Material Handling to offer a competitive lineup of robotic lift trucks to suit any application. Our robotic solutions are very robust. They are all very compatible with most warehouse management systems (WMS), and are flexible enough to have their routes adjusted in real-time. They can even be switched to manual mode with just the touch of a button. These solutions include:

End Riders

Yale’s robotic end rider uses a barcode scanner to ensure it transports the correct pallets. It can load both single and double pallets, run short or long distances, and lift a maximum capacity of 8,000 lbs. with ease. Investing in this end rider will assist you in improving efficiency when transporting materials.

Tow Tractors

When it comes to stock replenishment and material hauling, the robotic tow tractor is the truck you need. It can haul up to 15,000 lbs. in a standard trailer configuration. It’s also great for sequencing in assembly operations for highly precise work, and it can group separate items together to be supplied as a single unit.

Counterbalanced Stacker

If you need a tool to reach the second and third levels of your warehouse, invest in a counterbalanced stacker. It can operate in both horizontal and vertical applications without spending valuable dollars on additional infrastructure. With a capacity of 1,730 to 2,600 lbs., you can trust this truck to perform repetitive tasks without issue.

Reach Trucks

Robotic reach trucks can reduce high risk accidents. Falling items or tipping vehicles are very common and dangerous. A highly mobile, VNA-approved reach truck can deposit or remove pallets as high as 30 ft, helping you optimize your vertical storage while removing employees from potential fall zones.

Why Automate with Barclay Brand Ferdon?

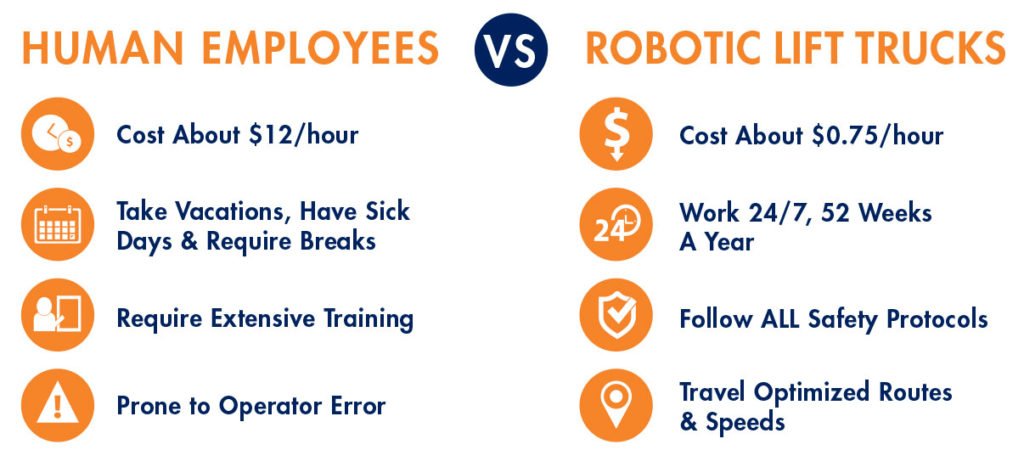

With the looming labor shortage across the nation, companies are investigating in the possibilities of automation – and for good reason. Skilled workers are becoming harder to find as experienced employees retire. Meanwhile, the warehousing industry faces added pressure to keep environments clean and safe. It gets challenging to meet these demands with less money, less space, and fewer qualified employees. Luckily, automation is quickly proving itself as an excellent solution with a huge return-on-investment. By automating repetitive tasks, companies can:

- Redirect human resources to roles that require them

- Enhance safety by reducing human error and accidents

- Improve efficiency on the work floor

Companies that combine human resources with automation can reduce their operating costs by up to 70%. Gain an edge over your competitors and begin automating your facility today with Barclay Brand Ferdon, which supplies robotic forklifts and other material handling solutions to businesses in North and Central NJ and select areas in NY. Contact us today to learn more about rentals, pre-owned equipment, and new offerings or to request a free quote.